¿Son los asientos de bicicleta cubiertos con cuero artificial más cómodos que los tradicionales para los usuarios habituales?

Confrontación de Materiales: Asientos de Bicicleta Artificiales vs Tradicionales

Entendiendo el Cuero de PU y Alternativas Sintéticas

Cuero PU , o cuero de poliuretano, es un material ampliamente utilizado en la producción de asientos de bicicleta. Se fabrica aplicando un recubrimiento de polímero flexible sobre un soporte de tela, lo que resulta en un material que imita la apariencia y el tacto del cuero genuino. Este enfoque sintético ofrece varias ventajas, principalmente su asequibilidad y versatilidad en términos de coloración y texturización. Además, Cuero PU es popular en la fabricación de asientos de bicicleta debido a su resistencia al agua y facilidad de mantenimiento. Junto con Cuero PU , alternativas sintéticas como el cuero de microfibra también están ganando terreno. El cuero de microfibra, compuesto de fibras ultrafinas, es conocido por su durabilidad y transpirabilidad, a menudo preferido para asientos de bicicleta premium.

Sin embargo, el impacto ambiental de la producción de estos materiales sintéticos no puede ignorarse. Informes indican que, si bien el cuero sintético requiere menos materias primas animales, su producción implica recursos no renovables. Esto podría resultar en mayores emisiones de carbono en comparación con el cuero tradicional. Aunque el cuero de PU es elogiado por ciertas iniciativas amigables con el medio ambiente, como reducir la dependencia de productos animales, la posible contaminación durante la fabricación sigue siendo una preocupación.

Cuero Tradicional: Atractivo Atemporal y Desafíos

El cuero tradicional tiene una historia destacada en el equipo de bicicleta, celebrado por su durabilidad y atractivo estético clásico. Los sillines de cuero aprovechan la fuerza natural y la flexibilidad de las pieles animales, lo que los convierte en una elección de larga data entre los ciclistas. Su capacidad para moldearse a la forma del jinete con el tiempo añade un confort personalizado que muchos ciclistas aprecian. Sin embargo, mantener el cuero tradicional puede ser desafiante debido a su sensibilidad a las condiciones climáticas y su necesidad de un mantenimiento regular.

Las estadísticas muestran que un asiento de cuero de alta calidad, con el cuidado adecuado, puede durar décadas, a menudo superando a sus contrapartes sintéticas. Esta longevidad subraya la practicidad del cuero a pesar de sus demandas de mantenimiento. La calidad estética, combinada con su resiliencia a largo plazo, tiene un fuerte atractivo. Sin embargo, también se debe considerar el equilibrio entre los requisitos de cuidado más rigurosos en comparación con las opciones sintéticas.

Diferencias clave en peso y transpirabilidad

Una de las principales diferencias entre los asientos de bicicleta de cuero sintético y tradicional es el peso. Los cueros sintéticos, como el cuero de PU, tienden a ser más ligeros en comparación con sus contrapartes tradicionales. Esta diferencia en el peso puede mejorar el rendimiento al pedalear, especialmente en ciclismo competitivo y a larga distancia, donde cada gramo cuenta. Por otro lado, la naturaleza más pesada del cuero tradicional se debe a sus fibras naturales densas que contribuyen a su durabilidad, pero puede no ser ideal para todos los ciclistas.

La transpirabilidad es otro factor crucial que impacta el confort del jinete. El cuero tradicional es naturalmente más transpirable, lo que permite una mejor circulación de aire y reduce la acumulación de humedad. Esta característica es particularmente beneficiosa durante largos recorridos. Las opiniones de expertos destacan que, aunque los materiales sintéticos están mejorando en su capacidad de imitación, rara vez igualan la transpirabilidad del cuero real. Esto es una consideración importante para atletas y trabajadores que buscan un rendimiento óptimo combinado con comodidad durante largos viajes.

Confrontación de Confort: ¿Qué Material Se Adapta Mejor?

Períodos de Amoldamiento: Sintético vs Cuero Genuino

El periodo de rodaje es un factor crítico al decidirse entre asientos para bicicleta de cuero sintético o genuino. Los asientos de cuero tradicional, como los fabricados por Brooks, requieren un tiempo considerable para adaptarse a la anatomía del ciclista, mejorando el confort con un uso prolongado. Muchos usuarios consideran esto una ventaja para lograr un ajuste personalizado. En contraste, los materiales sintéticos, como el cuero PU, ofrecen comodidad inmediata gracias a su naturaleza maleable y no necesitan un largo periodo de rodaje. Muchos ciclistas prefieren la satisfacción inmediata de los asientos sintéticos frente a la promesa de confort a largo plazo que ofrece el cuero genuino. Las encuestas realizadas entre los usuarios revelan una división entre los ciclistas, algunos valoran la capacidad adaptativa del cuero con el tiempo, mientras que otros prefieren la sensación constante de los materiales sintéticos desde el primer paseo.

Distribución de Presión y Soporte Anatómico

La elección del material del asiento de la bicicleta influye significativamente en la distribución de la presión y el soporte anatómico. Los asientos de cuero genuino, conocidos por moldearse gradualmente al cuerpo del jinete, proporcionan un soporte personalizado que potencialmente reduce los puntos de presión con el tiempo. Opciones sintéticas como el cuero microfibra están diseñadas para ofrecer una distribución uniforme de la presión, aprovechando la tecnología para crear diseños anatómicamente amigables desde el principio. Estudios sobre ergonomía en el ciclismo sugieren que, aunque la personalización del cuero con el tiempo es insuperable, los materiales sintéticos a menudo destacan al proporcionar un soporte anatómico consistente sin necesidad de un período de adaptación. Los testimonios de los ciclistas suelen resaltar cómo los asientos sintéticos mantienen el confort en diversas condiciones de conducción, mientras que los asientos de cuero tradicionales mejoran el soporte después de un uso extensivo, presentando un valioso compromiso para los ciclistas.

Impacto de la Resistencia al Clima en el Confort de la Conducción

La resistencia al clima desempeña un papel fundamental en la comodidad experimentada por los ciclistas, especialmente en climas variables. El cuero de PU y otras opciones sintéticas suelen destacar en la resistencia al agua y la adaptación a los cambios de temperatura, lo que los hace ideales para condiciones meteorológicas impredecibles. El cuero tradicional, aunque duradero, puede ser susceptible a daños por agua y fluctuaciones de temperatura, requiriendo más mantenimiento para preservar la comodidad y longevidad. Los datos sugieren que los materiales sintéticos mantienen mejor su forma y propiedades de acolchado en condiciones lluviosas o temperaturas extremas en comparación con las alternativas de cuero. Los expertos enfatizan que, aunque el cuero sintético ofrece un rendimiento superior en todo tipo de climas, algunos ciclistas aún prefieren las características de envejecimiento del cuero genuino, aceptando el compromiso por su atractivo clásico y sensación única.

Análisis de Durabilidad: Longevidad de los Materiales de la Silla de Bicicleta

Propiedades Impermeables del Cuero Artificial

Al examinar las cualidades impermeables del cuero artificial, queda claro que las opciones sintéticas superan al cuero tradicional. A diferencia del cuero genuino, que requiere mantenimiento regular para mantener su resistencia a la humedad, el cuero artificial suele ser inherentemente impermeable. Esto se debe a una capa de poliuretano que proporciona una protección efectiva contra la penetración del agua. Según estándares específicos, el cuero PU mantiene su característica impermeable con un uso prolongado. Estudios de casos anecdóticos sugieren que el cuero microfibra, una forma de cuero sintético, tiene un rendimiento excepcional en condiciones húmedas, manteniendo su durabilidad sin desgaste significativo. Además, el proceso de tratamiento impermeabilizante difiere entre estos materiales. El cuero tradicional a menudo requiere productos externos impermeabilizantes que se desgastan, mientras que el cuero PU ofrece una resistencia al agua incorporada.

Resistencia a los rayos UV y preocupaciones por el desvanecimiento

En cuanto a la resistencia a los rayos UV, el cuero sintético se comporta mejor en comparación con el cuero tradicional para mantener su apariencia bajo una exposición prolongada al sol. Los estudios indican que los materiales sintéticos, como el cuero de PU, muestran tasas de desvanecimiento más lentas y mantienen su color con el tiempo gracias a la protección UV incorporada. En contraste, el cuero tradicional tiende a desvanecerse más rápidamente a menos que se trate con productos resistentes a los rayos UV. Los datos de investigación respaldan que el cuero sintético puede soportar diversas condiciones ambientales, lo que aumenta su durabilidad y reduce los esfuerzos de mantenimiento. Sin embargo, para ambos materiales, rutinas de mantenimiento regular —como aplicar tratamientos protectores contra los rayos UV para fibras naturales o limpiezas regulares para los sintéticos— pueden ayudar a mitigar el desvanecimiento y prolongar la estética de las sillas de bicicleta.

Reparabilidad de Opciones Tradicionales vs Sintéticas

La reparabilidad varía significativamente entre el cuero tradicional y las opciones sintéticas. El cuero genuino, aunque duradero, a menudo requiere procesos de reparación especializados, que pueden ser costosos. Estos incluyen tratamientos de condicionamiento y parches para rayones o desgarres. Mientras tanto, el cuero sintético, como las variedades de PU o microfibra, generalmente permite reparaciones más simples y económicas, a veces solo requiriendo parches adhesivos o costuras menores. Los datos estadísticos indican que las necesidades comunes de reparación, como arreglar abrasiones o volver a sellar superficies, son más fáciles de abordar en el cuero sintético. Desde una perspectiva de sostenibilidad, los sintéticos tienen una ventaja económica debido al mínimo desperdicio de materiales de reparación y el generalmente mayor tiempo de vida antes de necesitar reparaciones profesionales. Esto los hace no solo una opción económicamente viable, sino también una opción sostenible para un uso continuo.

Al analizar estos aspectos—calidad impermeable, resistencia a los rayos UV y reparabilidad—podemos comprender mejor el panorama de durabilidad de los materiales para asientos de bicicleta, ayudando a los ciclistas a tomar decisiones informadas según sus necesidades individuales y condiciones ambientales.

Soluciones de Asientos de Bicicleta de Cuero Sintético MICOOSON

Cuero Sintético para Decoración de Muebles: Adaptación para Asientos de Bicicleta

El cuero sintético, inicialmente popular para la decoración de muebles, ha encontrado una nueva aplicación en los asientos de bicicleta, combinando tanto estética como funcionalidad. Este cambio está impulsado principalmente por la versatilidad y calidad del cuero sintético, como se ve en productos como el Cuero sintético para decoración de muebles .

Estos materiales han mostrado un rendimiento notable en aplicaciones de bicicletas al ofrecer durabilidad y resistencia al clima. Las últimas tendencias incluyen el uso de cuero sintético para crear diseños de bicicletas que no solo enfatizan el estilo, sino que también mejoran la comodidad y la resistencia del usuario durante los paseos.

Tela de Cuero Falso PVC: Rendimiento Grippi

El cuero falso de PVC es otro material innovador que está transformando las experiencias de las sillas de bicicleta, especialmente destacado por su rendimiento Grippi. Se destaca por mejorar el agarre y la comodidad durante el ciclismo, lo que lo convierte en una opción preferida sobre el cuero tradicional en escenarios de ciclismo exigentes. Productos como Material Grippi de tela de cuero sintético para muebles de PVC reflejan estas cualidades de manera notable.

Los ciclistas han señalado a menudo el agarre superior que proporciona el cuero de PVC durante los paseos enérgicos, lo cual queda aún más sustentado por diversas experiencias de usuarios y demostraciones en videos del mundo real. La adaptabilidad y alto rendimiento en condiciones dinámicas de bicicleta destacan a este material.

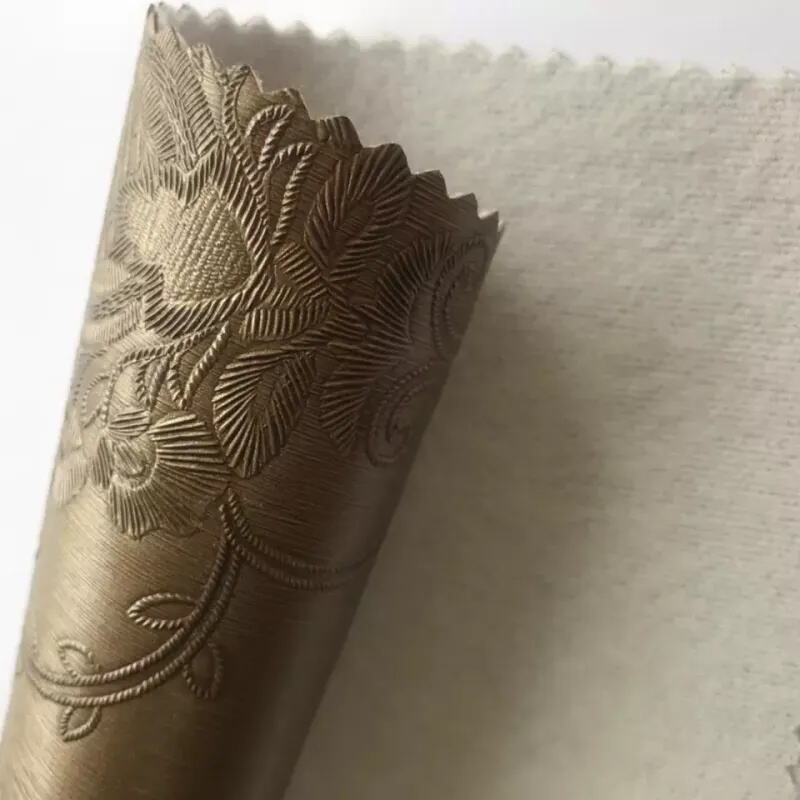

Opciones de Embossing Personalizadas para un Confort Personalizado

El embossing personalizado en cuero sintético ofrece una personalización y comodidad sin igual para los asientos de bicicleta. Esta característica es una ventaja significativa ofrecida por MICOOSON, permitiendo a los ciclistas elegir estilos que se ajusten exactamente a sus necesidades y preferencias.

Productos como el Cuero PVC con relieve demostrar esta capacidad de personalización, proporcionando tanto beneficios estéticos como prácticos.

Los testimonios de los usuarios a menudo destacan el mayor confort y satisfacción obtenidos gracias a estos diseños personalizados. Esta flexibilidad en el diseño adaptable, combinada con técnicas de producción meticulosas, subraya el compromiso de MICOOSON de adaptar productos para ofrecer la mejor experiencia al ciclista moderno.

Guía de mantenimiento: Conservar tu sillín de bicicleta

Limpiando cuero sintético sin causar daño

Mantener la condición impecable de los asientos de bicicleta de cuero sintético requiere seguir prácticas de limpieza específicas. Para evitar daños, utiliza jabón suave y agua o un limpiador dedicado para cuero sintético, evitando químicos fuertes y abrasivos. Comienza sacudiendo ligeramente el asiento con un paño de microfibra para eliminar la suciedad superficial. Luego, aplica el limpiador usando un paño húmedo, frotando suavemente la superficie. Después, asegúrate de secarlo con un paño suave y limpio para prevenir manchas de agua. El mantenimiento regular es clave: apunta a una rutina de limpieza mensual para mantener la calidad y apariencia del asiento. En comparación con el cuero tradicional, las opciones sintéticas generalmente son más fáciles de mantener ya que resisten el agua y las manchas, requiriendo menos esfuerzos de limpieza intensiva.

Condicionado de Sillas de Cuero Tradicionales

Los sillineras de cuero tradicionales requieren un cuidado meticuloso para preservar su flexibilidad y extender su vida útil. Comience utilizando un buen condicionador de cuero, aplicándolo con un paño suave para prevenir grietas y sequedad. Este proceso debe realizarse cada pocos meses o según sea necesario en función de la exposición del sillin a elementos ambientales. El cuidado adecuado no solo protege, sino que también mejora el confort y la apariencia del sillin, contribuyendo a una experiencia de equitación mejorada. Los especialistas en cuidado de cuero recomiendan evitar el exceso de condicionamiento, ya que podría saturar y dañar el cuero. Siempre permita que el producto se absorba completamente antes de usarlo, y evite utilizar condicionadores con químicos agresivos u aceites en exceso.

Consejos de almacenamiento para una mayor durabilidad del material

El almacenamiento adecuado de los asientos de bicicleta es crucial para prolongar la vida de sus materiales, especialmente al considerar la temperatura, la humedad y la exposición a la luz. Evite dejar los asientos de bicicleta expuestos al sol directo o en entornos demasiado húmedos, lo que puede causar desvanecimiento, agrietamiento u otras deterioraciones. Para obtener los mejores resultados, guarde su bicicleta en un lugar fresco y seco, idealmente con un clima estable. El cuero sintético, aunque más resistente, también puede sufrir por condiciones de almacenamiento deficientes, volviéndose frágil con el tiempo. El cuero tradicional, conocido por su sensibilidad a los cambios climáticos, se beneficia enormemente de estas medidas de almacenamiento cuidadoso. Los principales expertos de la industria recomiendan usar protectores de silla y mantener las áreas de almacenamiento limpias y libres de plagas para asegurar su durabilidad.

EN

EN