Flame-Retardant PU Leather Specs for Public Transport Seating

Composition and Fire-Resistant Properties of PU Leather

Scientific Properties of Polyurethane Materials in Fire-Resistant Applications

The segmented nature of polyurethane molecules creates both rigid parts made from aromatic isocyanates and flexible sections derived from polyols. This unique combination gives the material natural fire resistance properties. When exposed to high temperatures, the hard segments create stable crystal structures that can withstand heat without breaking down until around 300 degrees Celsius, which helps slow down burning processes. Meanwhile, when heated, the softer parts actually bend and stretch instead of catching fire, taking in thermal energy and making it harder for flames to spread quickly. Because of this two-part behavior, PU leather products can pass strict fire safety tests such as those specified under EN 45545-2 requirements while still keeping their pliability. Recent studies in polymer science have confirmed these characteristics, showing why manufacturers continue to prefer this material for applications where both safety and comfort matter.

PU Leather Composition and Construction for Enhanced Safety

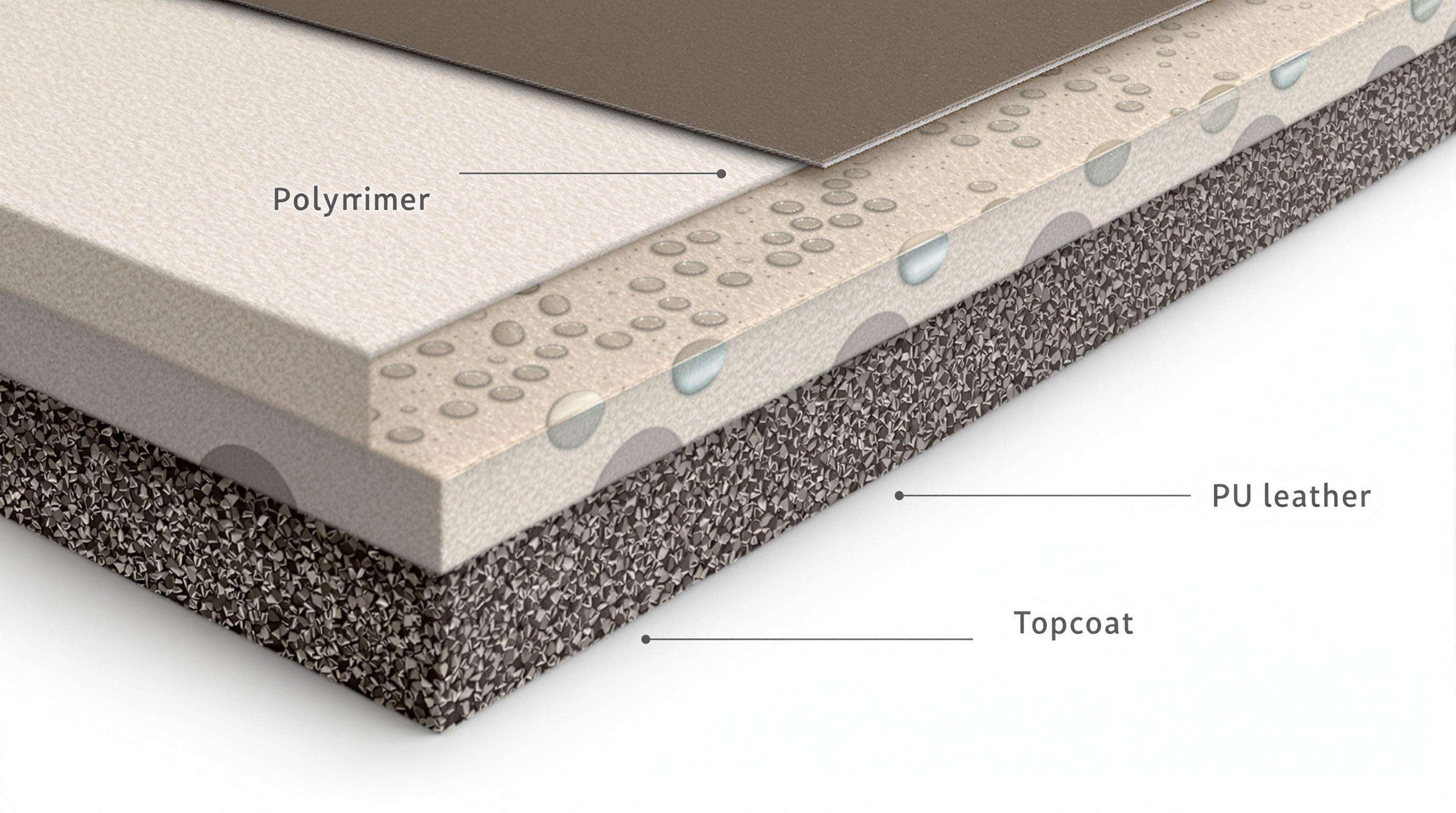

Flame-retardant PU leather employs a three-layer safety architecture:

- Base fabric: High-density polyester with ≥300 N/cm² tensile strength for tear resistance

- PU matrix: Crosslinked polymers infused with melamine-based microcapsules

- Topcoat: Resin with dispersed nano-alumina particles to limit oxygen diffusion

This design suppresses smoke density to <200 Ds (ISO 5659-2) and prevents molten dripping during combustion, addressing key fire hazards in public transport.

Role of Polymer Matrix in Flame-Retardant Performance

The polyurethane backbone contributes to fire resistance through two mechanisms:

- Carbonization between 400–500°C forms an insulating char layer (0.5–2 mm thick)

- Endothermic decomposition absorbs 3–5 kJ/g of heat

Studies show formulations with 15–20% biobased content retain these properties while reducing VOC emissions by 40% compared to conventional petrochemical-based PU.

Additives and Chemical Treatments Enhancing Fire Resistance

Manufacturers enhance PU's natural resistance using synergistic additives:

| Additive Type | Function | Performance Gain |

|---|---|---|

| Phosphorous esters | Gas-phase radical quenching | 35% slower flame spread |

| Nitrogen compounds | Char reinforcement | 50% higher LOI (Limiting Oxygen Index) |

| Inorganic hydroxides | Endothermic cooling | 60% lower peak heat release rate |

These work in tandem—aluminum trihydrate releases water vapor at 180°C, while ammonium polyphosphate (APP) forms a protective phosphoric acid barrier at 250°C—extending ignition resistance to over 120 seconds in ASTM E1354 testing.

Global Fire Safety Standards for Public Transportation Materials

Regulatory benchmarks for fire-resistant materials in transit environments

Fire safety regulations for public transport focus mainly on controlling how fast flames spread, reducing smoke production, and minimizing harmful emissions. Any materials used need to pass independent tests measuring several key factors. The heat release should stay below 100 kW per square meter, smoke density needs to be under 200 Ds, and after the initial flames go out, nothing should continue burning for more than 15 seconds. These strict guidelines help keep FlameRetardant PU Leather from breaking down too quickly when exposed to fire. This gives passengers critical extra time to get off the vehicle safely in case of an emergency situation.

Comparative analysis of flame-retardant requirements across regions (FMVSS 302, EN 45545, etc.)

The way different regions approach safety standards can be quite diverse when it comes to testing methods and what counts as acceptable. Take North America for instance, where the FMVSS 302 regulation relies on horizontal burn tests and sets a limit of 100 mm per minute for flame spread. Over in Europe, things work differently with their EN 45545 railway standard which uses vertical flame tests instead. Materials there get categorized into three hazard levels depending on where they'll actually be used throughout train systems. Meanwhile across Asia Pacific, particularly in China, the GB 8624 standard looks at something called the Limiting Oxygen Index and requires this value to average around 32%. All these variations mean manufacturers have to think carefully about how they design products if they want them to meet requirements everywhere they operate.

Case study: Compliance challenges in European rail seating

A 2022 update to EN 45545-2 revealed that 38% of flame-retardant PU leather samples exceeded new hydrogen cyanide emission limits (27 ppm). To comply, manufacturers eliminated halogenated additives and adopted phosphorus-nitrogen synergistic systems. This reformulation reduced HCN emissions to <20 ppm and improved smoke clearance by 40%, validated through 12-month durability simulations.

Testing Methods and Combustion Inhibition Mechanisms

How flame retardants on leather inhibit combustion

PU leather treated with flame retardants works against fires in several ways. First, it creates a protective char layer when exposed to high temperatures through carbonization. Then there's the release of gases like nitrogen and carbon dioxide that aren't flammable, which helps cut down on available oxygen. The material also absorbs heat during endothermic reactions, slowing down combustion processes. When these effects work together, they make a real difference. Additives containing phosphorus, nitrogen compounds, or minerals kick in when things get hot, significantly lowering how fast heat builds up. Studies from the Textile Research Journal back this up, showing reductions in peak heat release rates of around two thirds compared with regular untreated materials.

Standardized testing: Vertical burn, heat release rate, and smoke density

| Test Method | Measurement Focus | Compliance Threshold |

|---|---|---|

| Vertical Burn (FMVSS 302) | Flame spread speed | ≤100 mm/min |

| Heat Release Rate (ISO 5660) | kW/m² fire intensity | ≤90 kW/m² |

| Smoke Density (ASTM E662) | Visibility obstruction (%) | ≤200 Ds (4-min average) |

These tests simulate real-world fire scenarios using controlled environments. Cone calorimetry measures heat release rate—a key indicator of flashover risk—while NBS smoke chambers assess particulate density. Advances in combustion analysis now integrate real-time diagnostics to improve measurement accuracy for certification.

Industry paradox: Balancing toxicity of flame retardants with safety efficacy

Manufacturers are stuck between a rock and a hard place when it comes to flame retardants. Halogenated options such as brominated compounds work really well at stopping fires but create dangerous dioxins when they burn, which is why many countries have restricted their use through regulations like REACH. On the other hand, safer choices like aluminum trihydrate cut down on toxicity by about 84 percent according to Green Chemistry research from 2024. However these alternatives need much larger amounts in materials, something that often makes products less flexible overall. The situation gets even trickier because standards vary across regions. For instance, EN 45545-R1 still permits certain halogenated substances while California's TB 117-2013 rules actually require companies to use non-halogenated chemicals instead. As a result, manufacturers keep tweaking their formulas trying to find that sweet spot where products stay safe, last long enough, and meet all those different regulatory requirements without breaking the bank.

Durability, Performance, and Cost Efficiency in High-Traffic Transit Use

Durability and wear resistance of PU leather under high-traffic conditions

Flame-retardant PU leather excels in high-use transit environments due to its cross-linked polymer structure, maintaining integrity after 30,000+ abrasion cycles. It resists cuts, scuffing, and fatigue at stress points such as seat edges—unlike traditional fabrics that fray or thin over time—resulting in longer service life.

Abrasion, UV, and moisture resistance in public transport settings

Engineered for harsh conditions, premium PU leather includes UV stabilizers preventing color fade after 500+ hours of sun exposure. Hydrophobic polymer chains repel liquids, minimizing moisture absorption from spills or rain, while chemical-resistant coatings withstand daily industrial cleaning without degradation.

Long-term performance data from bus fleet seating trials (2020–2023)

U.S. and European bus fleet trials show flame-retardant PU leather maintained FMVSS 302 compliance beyond 250,000 usage cycles. After three years of service, 89% of test seats retained acceptable seam integrity—significantly outperforming vinyl alternatives, which exhibit cracking within 18 months under accelerated wear testing.

Cost-benefit analysis: Replacement frequency vs. initial material investment

Although flame-retardant PU leather carries a 20–30% higher upfront cost, its 7–10 year lifespan halves replacement frequency compared to 3–5 year vinyl options. Transit agencies report 37% lower lifecycle costs per seat when factoring in installation labor and service disruptions, making it a cost-effective choice for long-term operations.

Innovations and Future Trends in Flame-Retardant PU Leather Technology

Sustainable flame-retardant formulations: Bio-based and halogen-free options

We're seeing a big move in the industry towards greener flame retardants made from things like plant based phosphates and those nitrogen rich compounds, moving away from those harmful halogenated additives that have been around for so long. These days, companies are using recyclable monomers along with biodegradable polymers that actually pass all the strict REACH regulations and still hit those important UL94 V-0 standards for fire safety. Pretty cool stuff comes from nature too when we look at bio sourced materials. Take lignin and starch based systems for instance they cut down smoke density by about 30 percent according to ASTM E662 testing methods, which matters a lot in real world situations where visibility during fires can save lives. And best part? They don't compromise on performance either.

Nanotechnology-enhanced flame retardancy: Trends and feasibility

Coatings made with nano-engineered materials like graphene oxide or layered silicates work really well as thermal barriers, often delaying ignition times between 40 to 60 seconds when tested under ISO 5660 standards. The addition of carbon nanotubes boosts heat dissipation capabilities by around three times what we see in traditional methods. There's still some work needed to get those nanoparticles evenly distributed throughout the coating process, but industry experts generally agree these advanced materials can be scaled up for real world manufacturing applications despite current limitations.

Smart materials: PU leather with responsive fire protection

Next-generation PU leather integrates phase-change microcapsules that release fire-suppressing agents above 300°C. Thermochromic additives provide early visual warnings by changing color at 150°C. Intumescent systems expand to form 5 mm thick char layers, reducing heat transfer by 65% in simulated fires—demonstrating strong potential in proactive safety applications.

Integration with IoT-enabled seat monitoring for proactive safety

When thermal sensors and smoke detectors get connected to cloud based systems, they can send out warnings about dangers as soon as something goes wrong. Tests on transportation systems showed these setups actually reduced how long it takes for help to arrive by around 70%, though actual results may vary depending on location specifics. The real magic happens behind the scenes where machine learning algorithms look at temperature changes across different areas, spotting potential fire hazards even before flames start flickering. And it doesn't stop there either. These smart systems keep an eye on how materials break down over time too. Once the protection level falls beneath what's considered safe, maintenance gets scheduled automatically. Some facilities report catching issues weeks earlier than traditional methods would have allowed, which makes all the difference in preventing disasters.

FAQ

What makes PU leather fire-resistant?

PU leather's fire resistance is due to the segmented polyurethane molecules which include both rigid and flexible parts. These provide stable crystal structures and energy absorption to slow down burning and flame spread.

How does flame-retardant PU leather benefit public transportation?

Flame-retardant PU leather can pass strict fire safety tests, minimizing fire hazards. Its construction reduces smoke density, limits flame spread and maintains structural integrity, giving passengers more time to evacuate in emergencies.

Are there sustainable options for flame-retardant PU leather?

Yes, industry developments include bio-based and halogen-free flame retardants which meet regulatory standards while reducing toxicity, making them a more sustainable choice.

What are the cost advantages of using flame-retardant PU leather?

Despite higher upfront costs, flame-retardant PU leather has a longer lifespan and lower replacement frequency, resulting in approximately 37% lower lifecycle costs compared to vinyl materials.

EN

EN