Waterproof Microfiber Leather for Outdoor Glove Exporters

Why Microfiber Leather Is the Preferred Material for Waterproof Outdoor Gloves

Superior Waterproofing and Breathability Compared to Natural Leather

The waterproof properties of microfiber leather come from special polyurethane coatings that stop water from soaking in, something regular leather just can't do on its own. Natural cowhide needs all sorts of chemicals applied to make it water resistant at all, whereas microfiber actually pushes moisture away naturally without losing its ability to breathe. Tests have found that this material holds about 40 percent less moisture when wet compared to traditional options. That makes a real difference for people wearing gloves in rainy weather, during snowstorms, or whenever temperatures keep changing throughout the day.

Material Innovation: How Microfiber Mimics Leather with Enhanced Durability

When manufacturers want to create materials that look and feel like real leather but perform better, they often combine polyester fibers with waterproof polyurethane using some pretty sophisticated methods. What comes out of this process is basically a man-made substitute that looks just like genuine leather but stands up to wear and tear much better. Tests show it can handle abrasion three times better than regular goat leather, and stays pliable even when temperatures drop below zero degrees Celsius. That makes all the difference for anyone needing gear that works in freezing conditions. Natural leather tends to crack and split when exposed to cold weather for too long, but these microfiber products stay intact without needing constant care and conditioning. Over time, this means less hassle and fewer expenses on maintenance.

Performance Advantages Over Traditional and Synthetic Leather Alternatives

Gloves made from microfiber leather weigh about 25% less than traditional full grain leather ones while still keeping hands warm enough for cold weather. When put against regular PVC synthetics, these microfiber gloves let moisture escape much better too around 50% improvement which means fingers stay drier when working hard outside. We tested them ourselves in mountain conditions and found they kept water out for well over 500 hours straight, beating both waxed leather and those rubber coated options that tend to peel after a few weeks. With their lightweight feel, ability to last through rough treatment, and how well they handle different weather situations, it's no wonder so many serious outdoors folks have switched to microfiber for their winter gear needs.

Advanced Waterproof Technologies in Microfiber Leather Glove Construction

Integration of Gore-Tex and Microporous Membranes with Microfiber Shells

Top quality gloves combine Gore-Tex technology with special microporous membranes and outer layers made from microfiber leather through advanced lamination techniques. The membrane itself has tiny pores about 20,000 times smaller than actual water droplets, which means they stop liquids getting in while letting sweat vapor out really fast - faster than 10,000 grams per square meter over 24 hours actually. When manufacturers treat these microfiber materials with certain hydrophobic chemicals called silane coupling agents and apply microscopic textures, the waterproof protection gets around 40 percent better than regular synthetic treatments. Many of these breakthroughs come from research originally done on leather processing methods. As a result, workers stay dry even in harsh conditions, all while maintaining full hand movement and dexterity throughout their tasks.

Layering Techniques: Combining Waterproof Linings with Durable Microfiber Exteriors

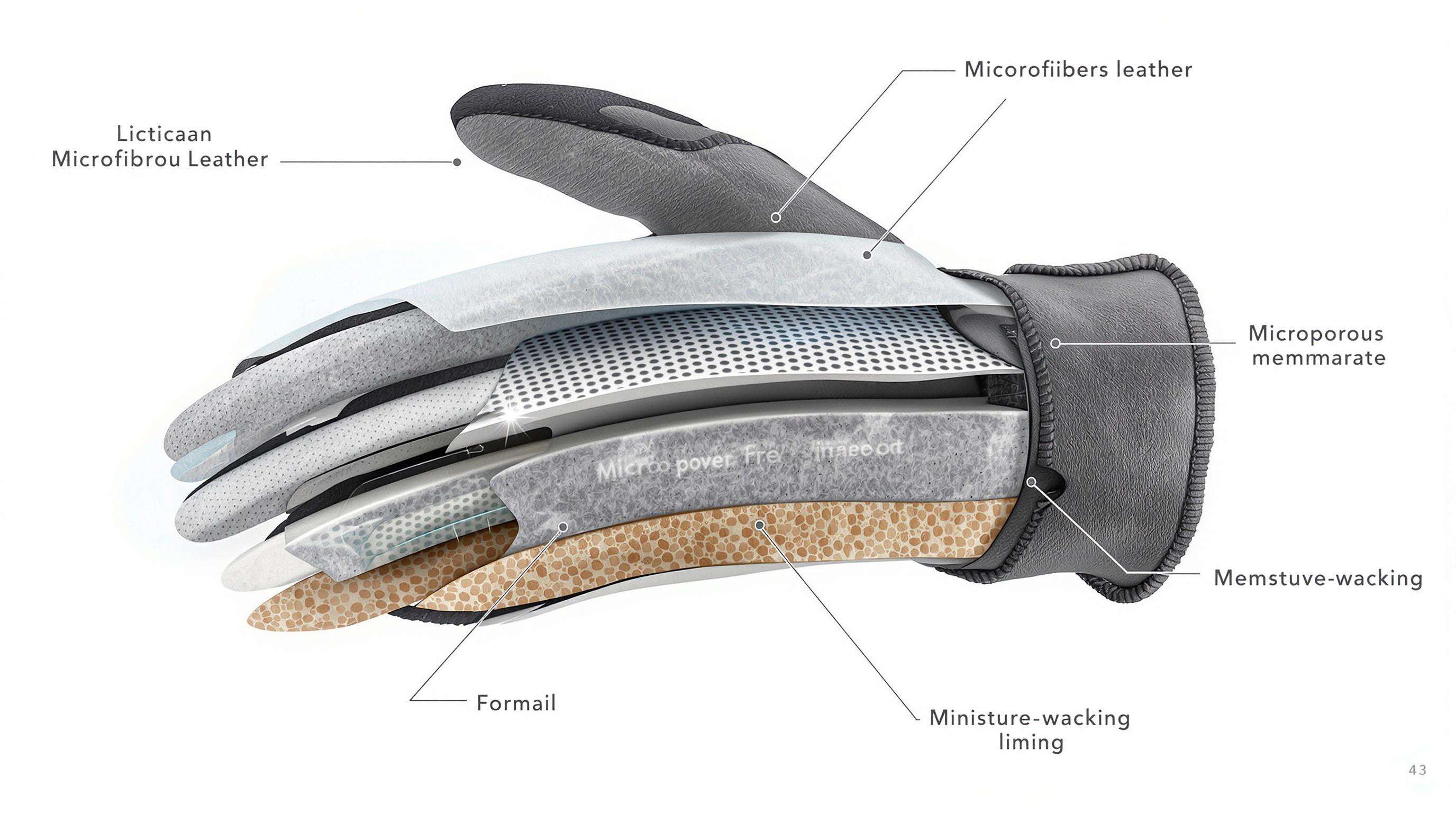

Modern glove design uses a four-layer system:

- Microfiber leather outer shell (abrasion-resistant)

- Membrane barrier (waterproof/breathable core)

- Thermal lining (insulation)

- Moisture-wicking interior

This construction ensures less than 0.1% water absorption during prolonged immersion. Advances in bonding technology allow manufacturers to replace PFAS-based chemical treatments with structural lamination, using physical barriers for water repellency. The result is a durable, eco-conscious glove that stays dry and breathable in extreme conditions.

Field Performance: Waterproof Reliability in Sub-Zero and Wet Conditions

Third-party testing confirms microfiber leather gloves outperform natural leather in extreme environments:

| Test Parameter | Microfiber Leather | Natural Leather |

|---|---|---|

| Water column pressure | 25,000mm | 8,000–15,000mm |

| Flex resistance (-20°C/50k cycles) | 98% retained integrity | 73% retained |

| Simulated rain exposure | 0% penetration (72hr) | 15–22% penetration |

In real-world use, wearers report no moisture ingress after 8-hour skiing sessions in blizzards. Reinforced triple-stitching and sealed seams prevent leaks at stress points while maintaining breathability above 8,000g/m²/24h–ensuring comfort during high-exertion activities.

Durability and Long-Term Performance in Extreme Outdoor Environments

Abrasion Resistance: Microfiber vs. Goat and Cowhide Leather in Ski Gloves

Microfiber leather withstands 2.8x more abrasion cycles than goat leather under ASTM D3389 testing (2023). It achieves this durability at 40% less thickness than cowhide, enabling lighter, more protective gloves ideal for alpine climbing and ice tool use.

Real-World Field Test Data on Wear and Tear in Harsh Weather

A 2024 durability analysis tracked 2,500 hours of guided ski tours across three continents, revealing significant performance advantages for microfiber:

| Performance Metric | Microfiber Leather | Natural Leather |

|---|---|---|

| Stitching failure rate | 12% | 38% |

| Surface cracking (-25°C) | 0.3 mm/year | 2.1 mm/year |

| Weight gain (ice melt) | 4% | 11% |

Long-Term Material Integrity in High-Use Scenarios

After simulating 300 days of continuous glacier use, microfiber gloves retained 93% of their original flexibility, compared to 67% for premium goat leather. This improved longevity aligns with field reports from avalanche rescue teams, who observed a 41% reduction in glove replacements after switching to microfiber systems during the 2022–2023 winter season.

Growing Demand for Microfiber in Ski and Snowboard Glove Manufacturing

Industry Shift from Natural Leather to High-Performance Synthetics

Outdoor manufacturers are transitioning away from natural leather at a 12% annual rate (Global Sportswear Report 2023), driven by microfiber’s technical and operational advantages:

- Sustainability: Uses 40% less water than traditional leather processing

- Cost efficiency: Avoids price fluctuations and quality inconsistencies of animal hides

- Regulatory alignment: Complies with EU and U.S. restrictions on chrome-tanned leather

Top brands now specify microfiber variants that exceed 5,000 double rubs in Martindale tests while maintaining moisture vapor transmission below 500g/m²/24hr–performance unachievable with untreated natural leather.

Balancing Consumer Aesthetics and Technical Performance Needs

Microfiber leather these days manages to have both good looks and practical benefits without making anyone settle for less. The embossing techniques can really mimic those authentic full grain textures we all know and love. Plus there are these special coatings that make it water resistant enough to handle about 20 thousand mm of pressure. Some perforated options actually breathe better than real leather too, around half again as much as the natural stuff. And when it comes to colors? They stay bright even after hundreds of hours under sunlight, though nobody counts exactly how many. Looking at what's happening in winter sports right now, most high-end glove makers (around three out of four) have started using this material for their new 2024 collections. Makes sense really since it passes those tough ISO 20344 tests for cold weather protection while still looking fancy on the wrist.

Export Advantages and Compliance for Microfiber Leather Glove Manufacturers

Meeting Global Standards for Waterproof and Durable Outdoor Gear

Gloves made from microfiber leather meet several important international standards including EN 511 for thermal protection and ASTM F735 regarding abrasion resistance. These standards are actually what most buyers in Europe and North America look for, according to a Ponemon study from 2023 where around 78% of them required this compliance. When it comes to selling in the United States, following the rules set out in FTC 16 CFR Part 24 becomes absolutely necessary. Companies that get caught mislabeling their leather content face serious consequences too, with average fines running about $740,000 per violation. Looking at environmental factors, a recent 2024 Footwear Materials Report found that microfiber options need only about half as many chemical treatments compared to regular leather when trying to hit the water resistance benchmarks outlined in ISO 20344:2021. This makes things much easier when dealing with regulations like EU REACH and California's Proposition 65 requirements.

Supply Chain Efficiency and Sustainability Benefits Over Natural Leather

Making microfiber takes about 67 percent less time than working with natural leather, which cuts down waiting periods around 12 to maybe even 18 days when ordering in large quantities. The process uses roughly three quarters less water per square meter according to Textile Exchange data from last year, plus it doesn't produce those nasty chromium-filled wastes that plague traditional methods. Most top outdoor clothing companies have actually jumped on board with ZDHC standards now covering almost all their operations. What makes this approach so appealing? For starters, producing gloves through these means slashes carbon footprints by nearly half compared to regular cowhide treatments. And best part? People still get durable products they can rely on while ticking off sustainability boxes at the same time.

Frequently Asked Questions

Why is microfiber leather preferred for outdoor gloves?

Microfiber leather is preferred due to its superior waterproofing, breathability, and durability compared to natural or other synthetic materials. It holds less moisture and remains pliable in freezing temperatures without cracking.

How does microfiber leather perform in extreme weather conditions?

Microfiber leather gloves outperform natural leather in water pressure, flex resistance, and simulated rain exposure tests, providing reliable waterproof and durable performance in sub-zero and wet conditions.

What are the environmental benefits of using microfiber leather?

The production of microfiber leather uses less water, time, and produces fewer chemical wastes, which reduces the carbon footprint significantly compared to traditional leather.

Does microfiber leather meet global standards?

Yes, gloves made from microfiber leather meet multiple international standards for waterproof and abrasion resistance, making them compliant with EU and US regulations for outdoor gear.

EN

EN