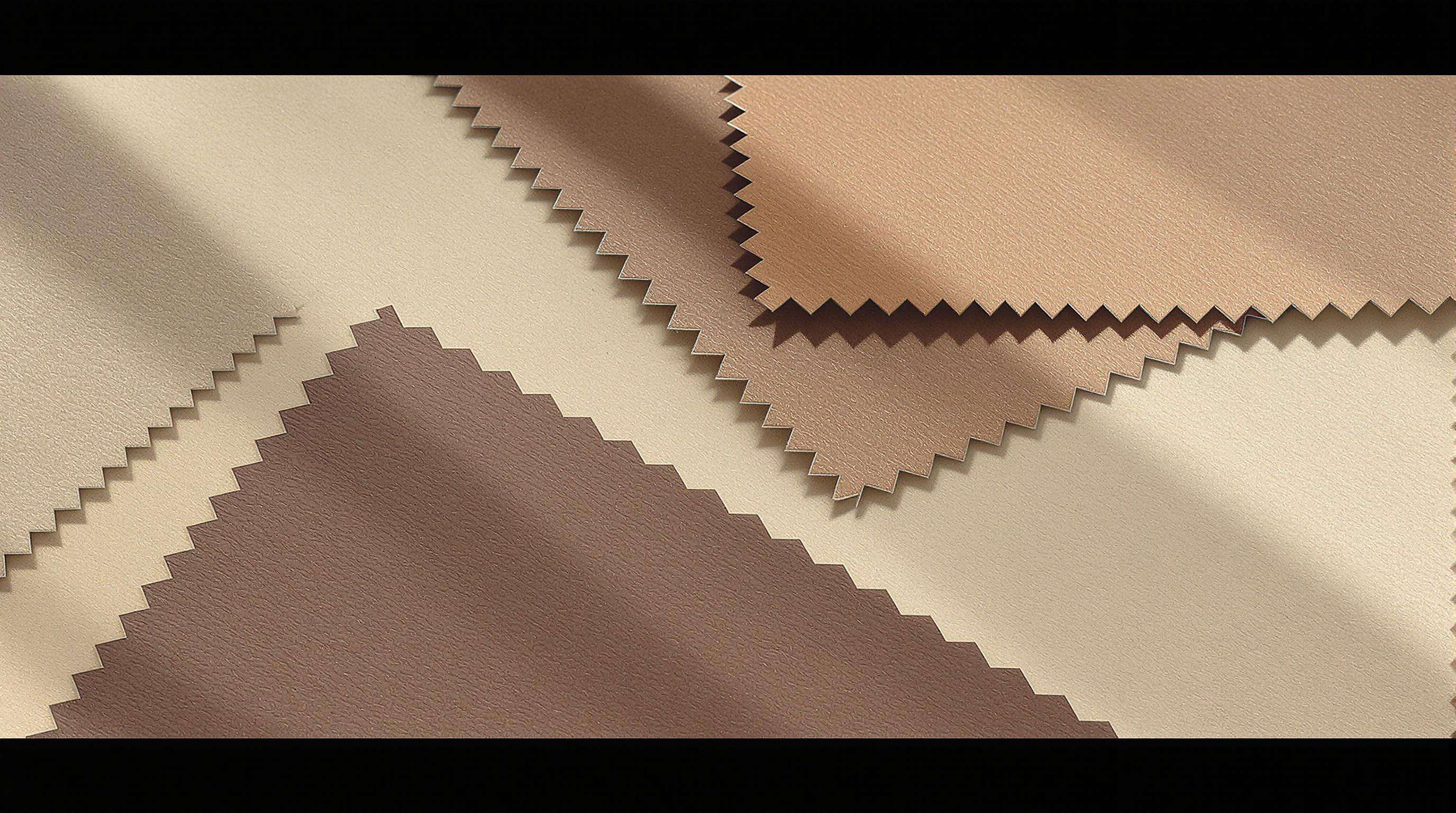

Recyclable Artificial Leather Options for Circular Economy Retailers

Understanding Recyclable Artificial Leather in a Circular Economy

Defining Recyclable Artificial Leather in Sustainable Retail

Artificial leather that can actually get recycled has been designed so it can either go through multiple uses, get processed again, or even break apart back into basic components. This makes it a much better option compared to regular synthetic leathers we see everywhere. Traditional stuff made from PVC or PU mixtures just won't budge when it comes to recycling efforts. But newer products are made with single materials like TPU or plant-based polymers instead. Retailers looking for greener options find these materials helpful because they cut down on what ends up in landfills and make it possible to recover large amounts of material over time. Some companies have already started implementing these changes in their supply chains.

Circular Economy Principles Applied to Synthetic Leather Production

The shift toward closed loop systems is really changing how synthetic leather gets made, focusing on materials that last longer while creating less trash overall. Manufacturers are adopting several approaches these days. For instance, they design items so parts can be taken apart easily later on. They also switch to water based glues that work better when trying to recycle stuff. And there's this neat practice where leftover bits from factories before anything reaches stores get put back into the production line again. A report from the Ellen MacArthur Foundation back in 2022 found something interesting too: around 60 percent of all leather waste actually happens during those early stages of making things at factories. That number alone shows why going circular makes so much sense for the industry right now. Some big names in the business have started turning scrap pieces from cutting rooms into fresh sheets of material already, and their test runs show waste getting diverted away from landfills at rates as high as 85 percent in certain cases.

Challenges in Material Separation and Scalability

Mixed-material compositions remain a major barrier to recycling artificial leather. A typical product contains 4–7 layers–including coatings, adhesives, and textile backings–requiring advanced separation technologies. Current mechanical recycling methods can process only 30–40% of post-industrial waste, highlighting the need for standardized material designs and expanded chemical recycling infrastructure.

Innovative Materials Driving Recyclable Artificial Leather

TPU-Based Synthetic Leather Recycling and Closed-Loop Potential

TPU, or Thermoplastic Polyurethane artificial leather, has this neat property where it can actually be heated up again and reshaped, which means we can create what's called a closed loop recycling system. When manufacturers melt down scrap material, they just reform it into new products rather than throwing it away. Compared to those old school PVC options, TPU keeps its bounce and color even after being recycled several times over. Some early tests show companies cutting their need for brand new raw materials by around 80%, though results vary depending on how things are processed. What really stands out about TPU though is how well it fits into current recycling infrastructure, making it one of the better options right now for creating something that works within our existing waste management systems instead of requiring entirely new facilities.

Plant-Based Alternatives: Myloâ„¢, AppleSkinâ„¢, and Next-Gen Bio-Based Materials

Innovations like mushroom-derived Myloâ„¢ and apple-waste-based AppleSkinâ„¢ utilize agricultural byproducts to create low-carbon, biodegradable leather substitutes. These materials are gaining rapid traction in luxury accessories, with 2025 industry reports indicating a 40% faster adoption rate compared to conventional synthetics.

Silk Protein Bonding Technology for Durable Recycled Leather

Silk fibroin coatings enhance the structural strength of recycled leather, increasing abrasion resistance by 65% while preserving breathability. This advancement addresses durability concerns that have historically limited the commercial viability of recycled materials, helping post-consumer products meet performance standards.

Dry Airlaid Manufacturing Process: Reducing Water Use by 90%

European manufacturers have pioneered a dry airlaid process that bonds fibers using air pressure instead of water-intensive wet lamination. This method reduces water consumption from 1,500 to 150 liters per square meter and cuts energy costs by 30%, making it one of the most resource-efficient production techniques available.

Material Comparison: Recyclability, Durability, and Scalability of Artificial Leather Options

| Material Type | Recyclability | Durability (ASTM tests) | Scalability |

|---|---|---|---|

| TPU-Based | Closed-loop | 200,000+ flex cycles | High |

| Plant-Based (Myloâ„¢) | Industrial | 150,000 flex cycles | Moderate |

| Silk-Reinforced Recycled | Mechanical | 180,000 flex cycles | Low |

| Dry Airlaid Production | Thermal | 220,000 flex cycles | High |

This analysis shows TPU and dry airlaid production as the most scalable options for circular economy retailers, combining high performance with strong recyclability and commercial feasibility.

From Waste to Resource: The Recycled Leather Production Process

From leather waste to raw feedstock: Fiber-processing techniques

Making recycled faux leather begins with special processing methods that turn industrial waste materials into something actually useful. Most of this waste comes from pre-consumer scraps, which account for around 60% of what gets thrown away in the industry. These scraps get broken down into tiny fibers and then attached to micro-textile bases through high pressure water streams. What comes out looks and feels similar to real leather but without all the environmental costs. This process saves significant amounts of water and keeps approximately 70% of potential landfill waste out of disposal sites instead.

Challenges in leather waste recycling due to mixed materials

Despite progress, mixed-material construction continues to hinder recycling. Polyurethane coatings, synthetic backings, and residual adhesives complicate separation, increasing processing costs by 15–20%. Material degradation during shredding also necessitates reinforcing layers, which can affect the final product’s flexibility and consistency.

Case Study: Circular design in action at a European footwear brand using 70% post-industrial leather scraps

A leading European footwear brand has implemented a closed-loop system using post-industrial leather scraps. By collecting factory offcuts–primarily artificial leather trim–they now produce sandals and bags with:

- 90% less water use than traditional methods

- 70% recycled content in new collections

- 32% lower carbon emissions per unit

This initiative diverts 18 tons of waste annually from domestic facilities, proving that scalable circular models are achievable in synthetic leather production.

Environmental Impact and End-of-Life Management of Artificial Leather

Comparative analysis: Carbon footprint of artificial leather vs. virgin leather

The leather industry is responsible for around 80% of all carbon emissions in footwear manufacturing. This comes mainly from methane produced by cattle and the heavy energy demands of traditional tanning processes. Artificial leathers made from petroleum products cut down on CO₂ emissions during manufacturing by roughly half to two thirds. However, some PVC versions create problems of their own because they release harmful chemicals as waste products. Now there are plant based alternatives available that slash emissions compared to regular plastics by as much as 72%. These newer materials seem to be making real progress toward solving the environmental issues that have plagued the industry for so long.

Life cycle assessment of bio-based synthetics

Third-generation plant-derived materials–such as those made from fruit waste–deliver significant environmental benefits. Independent assessments confirm:

- 94% less water use than bovine leather processing

- 80% smaller land footprint versus grazing requirements

- Full biodegradability within 180 days under industrial composting

When supported by proper recycling systems, these materials align effectively with circular retail models.

Controversy Analysis: Biodegradability claims vs. actual end-of-life recyclability

Many people get misled when they see claims about biodegradable artificial leather. The reality is pretty different from what most think. Less than 15 percent of items marked as compostable actually decompose in regular landfills because there just isn't enough heat or microbes to do the job properly. For something truly circular to work, we need standard ways to take these materials apart and clean out harmful chemicals first. But right now, nobody really has those systems figured out yet. Until companies build the proper facilities alongside their green innovations, talking about biodegradability stays mostly wishful thinking rather than something that actually works in practice.

FAQ Section

What is recyclable artificial leather?

Recyclable artificial leather is designed to be used multiple times, processed again, or reduced to basic components through recycling, unlike traditional synthetic leathers such as those made from PVC or PU.

Why is the circular economy important for synthetic leather production?

The circular economy reduces waste and promotes the reuse and recycling of materials, creating closed loop systems that minimize environmental impact and improve sustainability in synthetic leather production.

How does TPU-based synthetic leather contribute to the circular economy?

TPU-based synthetic leather can be heated and reshaped, allowing it to be recycled into new products, thus creating a closed loop recycling system that reduces waste and consumption of raw materials.

Are plant-based alternatives to artificial leather environmentally friendly?

Yes, plant-based alternatives like Mylo™ and AppleSkin™ use agricultural byproducts, offering low-carbon, biodegradable substitutes that reduce environmental impact compared to traditional synthetics.

What are the challenges in recycling artificial leather?

Challenges include mixed-material compositions and the need for advanced separation technologies, as current mechanical recycling methods are limited in processing post-industrial waste effectively.

EN

EN